This post contains affiliate links.

In the intriguing realm of balloon artistry, balloon regulators serve as quintessential equipment. These devices, specifically designed to control the flow of helium or other gases used to inflate balloons, ensure that we maintain impeccable accuracy and efficiency.

What Is A Balloon Regulator

A balloon regulator is a device used to control the flow of gas into a balloon. It ensures safe inflation and pressure maintenance for various balloon types, including weather balloons and gas-filled decorative balloons. This tool plays a critical role in maintaining buoyancy and structural integrity during flight or display.

How Does A Balloon Regulator Work

A balloon regulator, typically used for inflating balloons with helium, controls gas flow from a pressurized tank. It includes a valve, pressure gauge, and nozzle to ensure precise gas release, enabling controlled inflation of balloons.

Did you know there are even different types of balloon regulators?

Different Types of Balloon Regulators

There are, largely, two main types of balloon regulators: high pressure and low pressure. The type of balloon regulator you require will depend on several factors such as the gas you’re using, the type and size of balloons you have, and the event you’re planning.

High-Pressure Balloon Regulators

High-pressure balloon regulators are designed to withstand high pressure and are primarily used for inflating latex or rubber balloons. Since latex balloons are made of thick, rubbery material, they require more pressure to inflate.

These high-pressure regulators often come with a hand-tight cylinder connection and a rubber tilt valve for easy filling. The regulator can easily be manually adjusted to control the psi, giving you full control of the inflation rate.

Low-Pressure Balloon Regulators

Low-pressure balloon regulators are typically used for inflating Mylar or foil balloons. Mylar balloons are not as robust as latex balloons and therefore do not require high pressure for inflation. In fact, using high-pressure regulators for Mylar balloons can often result in damage or bursting.

These regulators also come with a hand-tight cylinder connection, but most often include a push valve for easy filling. Much like the high-pressure regulators, the low-pressure regulators allow for easy manual control of the psi.

Using Balloon Regulators

Using a balloon regulator is a straightforward process. Begin by securing the balloon regulator onto the gas tank. This can usually be done by hand, but sometimes tools may be involved. Once the connection is secure, you can attach the uninflated balloon to the valve of the regulator.

To inflate the balloon, turn or push the valve, allowing the gas to flow into the balloon. Be sure to constantly monitor the size of the balloon to prevent overinflation and potential bursting. Once the balloon has reached its desired size, turn or push the valve once again to stop the flow of gas.

When you’re done, disconnect the balloon regulator from the gas tank and store it securely for next time. It’s important to remember that all types of gas, including helium, are potentially dangerous, so make sure to handle equipment with care and store cylinders out of reach of children.

By understanding the different types of regulators and how to use them, you can confidently inflate balloons with ease and safety.

Understanding The Types Of Balloon Regulators

There are two main types of balloon regulators commonly used: Single Function Inflator and Conwin Duplicator 2. A single function inflator is designed solely for inflating balloons to the desired level of fullness. On the other hand, the Conwin Duplicator 2 comes with digital controls that allow for more precise inflation levels, making it the preferred choice for professionals who need to ensure consistent measurements.

How To Use Balloon Regulators

Balloon regulators, also known as balloon inflators, are devices used to control the flow of helium or air into balloons. They are critical tools for anyone in the balloon business or simply needing to fill up a large number of balloons quickly and efficiently. The two main types of regulators are the push valve and the auto shut-off valve. The push valve requires manual turning on and off, while the auto shut-off type automatically stops when the balloon is full.

How To Use A Push Valve Balloon Regulator

Things You Will Need

- balloon(s)

- helium tank

- helium tank regulator – if not attached to the tank

Attach Regulator (If not already attached)

The first step in using a push valve balloon regulator is to connect the regulator to the helium tank. To do this, first, ensure that the helium tank valve is closed.

Then, thread the end of the regulator onto the valve. Turn clockwise until the connection is tight to prevent leakage.

Open The Valve

Turn the helium tank valve counter-clockwise to open the helium tank valve.

Attach Balloon To Helium Tank Regulator

To inflate a balloon, slide the lip and neck of the balloon over the nozzle of the regulator. If you need more information about the part of a balloon, check out my post Parts Of A Balloon here.

Press Down Gently

Push down gently on the nozzle; this opens the valve and allows the helium to flow into the balloon. The balloon will start to inflate.

Inflate Balloon

Once the balloon reaches the desired size, let go of the nozzle to stop the flow of helium. For more information on how to properly size a balloon, check out my post Best Way To Size A Balloon here.

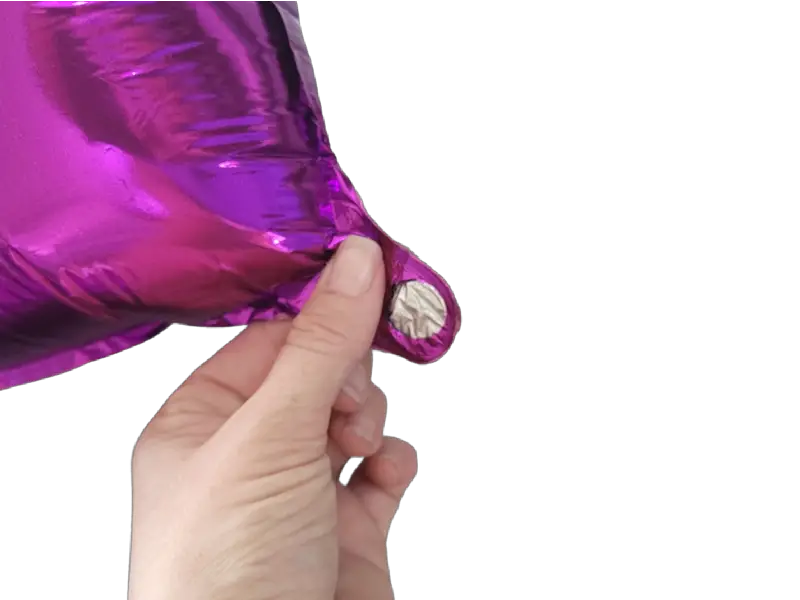

Remove Balloon From Helium Tank Regulator

Remove the balloon from the helium tank regulator, pinching the balloon neck as you remove the balloon, being careful not to let any helium escape.

Tie The Balloon (If Desired)

Tie the balloon to prevent the loss of helium. For more information on how to tie a balloon, check out my post Learn How To Tie A Balloon Like An Expert here.

Close The Valve

Turn the helium tank valve to the right to close the helium tank valve. Release the helium from the helium tank valve.

Always close the helium tank valve to prevent helium from leaking out of your helium tank.

Enjoy!

How To Use An Auto Shut-Off Balloon Regulator

What You Will Need:

- balloon(s)

- helium tank

- helium tank regulator

An auto shut-off balloon regulator operates on the same fundamental principles as a push valve model, but it adds an element of automation.

Attach Regulator

As with the push valve model, you start by connecting the regulator to the helium tank, ensuring that the helium tank valve is closed.

Then, thread the end of the regulator onto the valve. Turn clockwise until the connection is tight to prevent leakage.

Open The Valve

Turn the helium tank valve counter-clockwise to open the helium tank valve.

Attach Balloon To Helium Tank Regulator

Place the balloon over the nozzle of the regulator. Unlike with the push valve model, you only need to press down on the nozzle once, and the regulator will automatically stop once the balloon has reached its capacity. This prevents overfilling and balloon bursts.

Remove Balloon From Helium Tank Regulator

Remove the balloon from the helium tank regulator.

Tie The Balloon To A Balloon Weight

Tie the balloon to a ribbon and an adequate sized balloon weight. For more information about balloon weights check out my post, Balloon Weights: How To Use, Make And How Heavy They Need To Be here.

Check out my post on Smart Balloon Practices.

Close The Valve

Turn the helium tank valve to the right to close the helium tank valve. Release the helium from the helium tank valve.

Always close the helium tank valve to prevent helium from leaking out of your helium tank.

Enjoy!

Balloon Regulator Safety Precautions

There are safety precautions you should observe when using balloon regulators. Always ensure the helium or air tank is secure and upright before attaching a regulator. Don’t attempt to forcibly open the valve if it is stuck; instead, seek assistance or instruction from a professional. Lastly, helium should never be inhaled, even in small amounts, as it can displace oxygen and cause health complications.

It’s also important to wear eye protection when inflating balloons. Balloons can burst unexpectedly, sending small rubber fragments into the air. If working in a professional capacity, always follow the Occupational Safety and Health Administration’s (OSHA) guidelines for safe work practices.

Maintenance And Troubleshooting Balloon Regulators

Maintaining The Optimal Performance Of Balloon Regulators

Routine maintenance is pivotal in keeping your balloon regulators working efficiently. Begin by inspecting any visible parts for damage or wear and tear. A thorough visual inspection can help detect potential problems early and prevent unexpected breakdowns.

Periodically replace the cylinder seal, pressure relief valves, and other parts as recommended by the manufacturer. This not only ensures optimal performance but also extends the lifespan of the regulator.

Keep the regulator clean and free from dust and debris. Dust can accumulate in the vents and hinder the performance of the regulator. Clean the exterior with a damp cloth and soapy water, but remember to keep the water away from any mechanical parts or openings.

Troubleshooting Common Balloon Regulator Issues

Even with regular maintenance, balloon regulators can sometimes experience issues. If the regulator isn’t releasing helium gas, it could be due to a damaged or worn-out spring inside the valve. In this case, replace the spring as soon as possible.

Over time, the balloon regulator might start leaking helium. If this happens, check for a tight connection between the regulator and the cylinder. If the connection is secure but still leaking, it could be due to a worn-out seal. Always keep spare seals available for quick replacement.

If the pressure gauge isn’t giving an accurate reading, it can lead to either overfilled or underfilled balloons. This might signify damage to the gauge itself or a problem with the calibration. Seek expert help to recalibrate the gauge or replace it if necessary.

Understanding the type of balloon regulator you have, performing regular maintenance, and being aware of potential problems will ensure that your device stays in optimal working condition. Knowledge of common issues and their solutions can save time and prevent disruptions, ensuring your balloon decorations are always perfect.

Captivating as it may be, the world of balloons goes beyond just inflating them. It involves understanding high-pressure and low-pressure balloon regulators, accurately connecting them, adjusting settings, monitoring, and ensuring their maintenance.

Knowledge and understanding of the troubleshooting techniques can resolve potential issues and optimize the use of balloon regulators. Such expertise not only ensures the durability of your regulators but also guarantees the flawless execution of your balloon artistry. Let the sound understanding of balloon regulators create wonders for you in the domain of balloon artistry, taking it to unprecedented heights!

I hope this post brought value to your day. If it did, please consider sharing it with a friend or on your favorite social media. Thanks For Reading Fun With Balloons!